AP2006 Side Hinged Door

Operating Arm Kit

FITTING INSTRUCTIONS

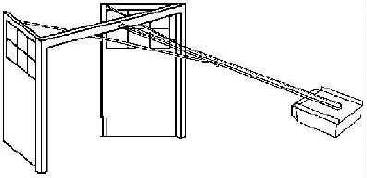

For the automation of

a pair of traditional outward

opening side hinged barn type garage doors

type AP2006/HD suits openings from 3.1mtrs to 3.6mtrs

For use with any electric garage door operator having

provision for safety stop logic reversal

Recommended operator: Seip TS75

The Seip TS75 operator has a very sophisticated self learning safety stop system to provide the high level of protection required on side hinged doors and also incorporates a safety stop logic reversal switch for outward opening doors to avoid the need for special modification when used on this type of door

1.

Close the doors and

check that the lapping edges are not jamming and that the doors are closing

properly at the bottom.

2.

Assemble the electric

operator according to the manufacturers instructions

and reverse the motor & limit switch connections so that the

motor's safety reverse function operates during door closure. (when trolley

is moving towards motor)

Note:- To do this on a Seip TS75 simply set DIP switch No.6 on the P.C.B. to the

“ON” position

3.

Fix the door header

track bracket 20mm above the bottom edge and centrally on the door frame

header.

4.

Install the electric

operator according to the manufacturers

instructions, keeping the track horizontal.

5.

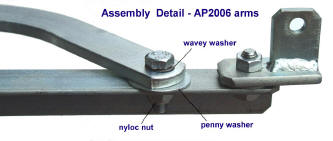

Lay the AP2006 door

arms on the floor, swap the arms if necessary to suit door handing by

reversing the 'L' arm (the hockey stick shaped bracket) thus

enabling the shortest arm (with the longer sliding travel) to be

attached to the door that is rebated to close first.

(as delivered, AP2006 arms are assembled for the LH leaf to close first

when viewed from outside)

Arms as delivered - configured for RH leaf to close first (when viewed from inside)

Arms shown reversed for LH leaf to close first (when viewed from inside)

1.

Make a pencil mark at

the top of both doors 1 mtr. from

the hinged edge.

(with AP2006/HD kit fix arms to doors at 1.2mtrs)

2.

Attach the arms to the

sliding trolley of the operator then fix the other ends of arms to the doors

at the 1 mtr. pencil marks

(using 8mm x 40mm coach-screws. Hint :- use a strap to support one arm while attaching the

other arm to the door.

3.

Lubricate all moving

& sliding parts with oil. (engine oil recommended)

Engage and carefully

run the electric operator and set the open & close limit stop

adjustments, use the 'open' limit adjustment to set the desired

stop position when fully open, the 'close' limit adjustment should

be set to stop the motor when the doors have closed and extended the sprung

loaded door arms.

Notes :-

1/ Check the safety-stop system and

make adjustments to the trip sensitivity if required,

the motor must reverse if the doors are obstructed while closing (see

step 2.)

2/ A cable

operated external release device should be fitted to enable manual operation in the

event of power failure if no alternative access is available.

3/ All moving parts should be

lubricated annually (engine oil recommended)

4/ To prevent loss & damage from

forced entry our Securi-Dor bottom locking kit model AP2007 Mk2 can be

fitted to automatically secure the doors at the

bottom when closed.

Securi-Dor AP2007 automatic bottom

locking upgrade kit for

use with AP2006

side hinged barn door arms

AP2007 Product details

AP2007 Mk2 Fitting Instructions

Amourelle Products, Unit 16 James

Scott Rd, Halesowen, West Midlands B63 2QT

Registered in England No. 03051720 - VAT

Reg. No. GB 695768459

Phone: 01384 900 264 - www.amourelle.co.uk